Exhibition Review ‖ To Depict New Blueprint of Biomedicine with Cutting-Edge Technologies and Latest Achievements

On October 16, CBioPC 2021 rounded off at Nanjing International Expo Center. The outbreak of COVID-19 in 2020 had not only propelled the technological innovation of the biopharmaceutical industry, but also given rise to many new ideas and new products with its extensive and far-reaching impact. The grand event in the golden autumn was certainly a good opportunity for people to gather and jointly discuss new ideas in the field of biologics.

Morimatsu has been deeply involved in the biopharmaceutical industry for more than 20 years, and has never ceased its pace of innovation. Instead, it keeps up with the new trends of market development, and constantly conducts upgrading and iteration of products and services. Morimatsu exhibited its desktop reactor system, inline buffer dilution system, and disposable liquid mixing system, which grabbed the attention of many visitors.

Desktop reactor system

Applied to lab-scale test, R&D, laboratory, individual-based treatment (CAR-T), using industrial-grade PLC, E&I components and commercial industrial configuration platform, featuring simultaneous control of multiple devices, remote monitoring and data collection, flexibly used in single-stage or parallel tests. Volume optional from 1L-10L, 2-16 units in parallel, applicable to batch and continuous perfusion culture of bacteria and cells.

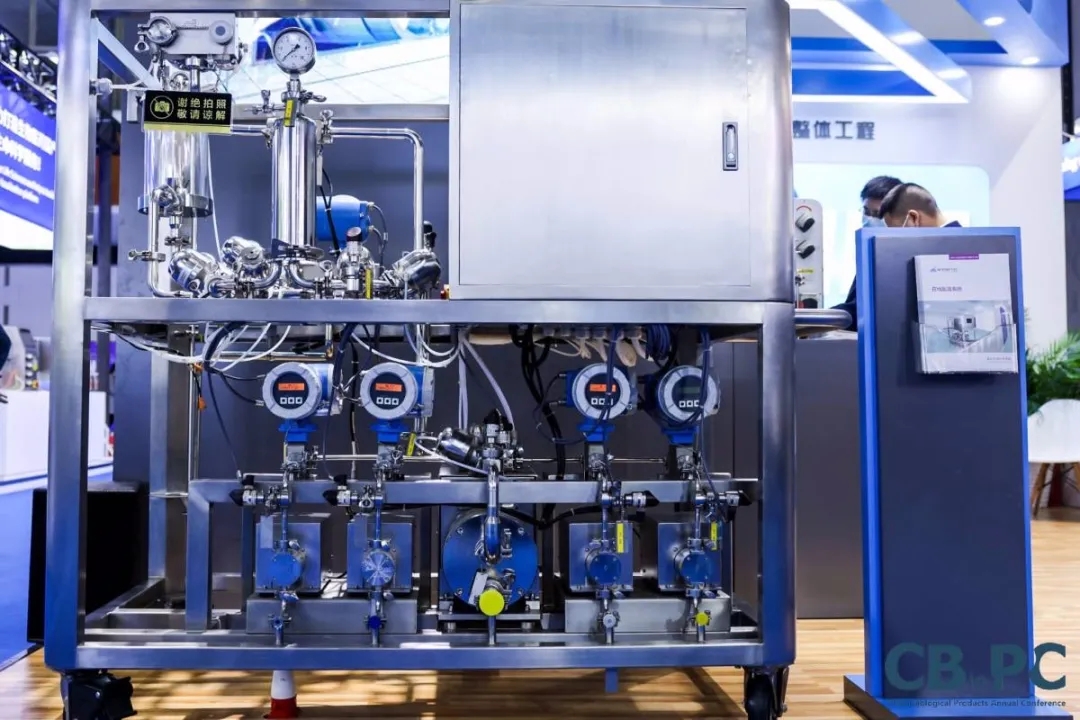

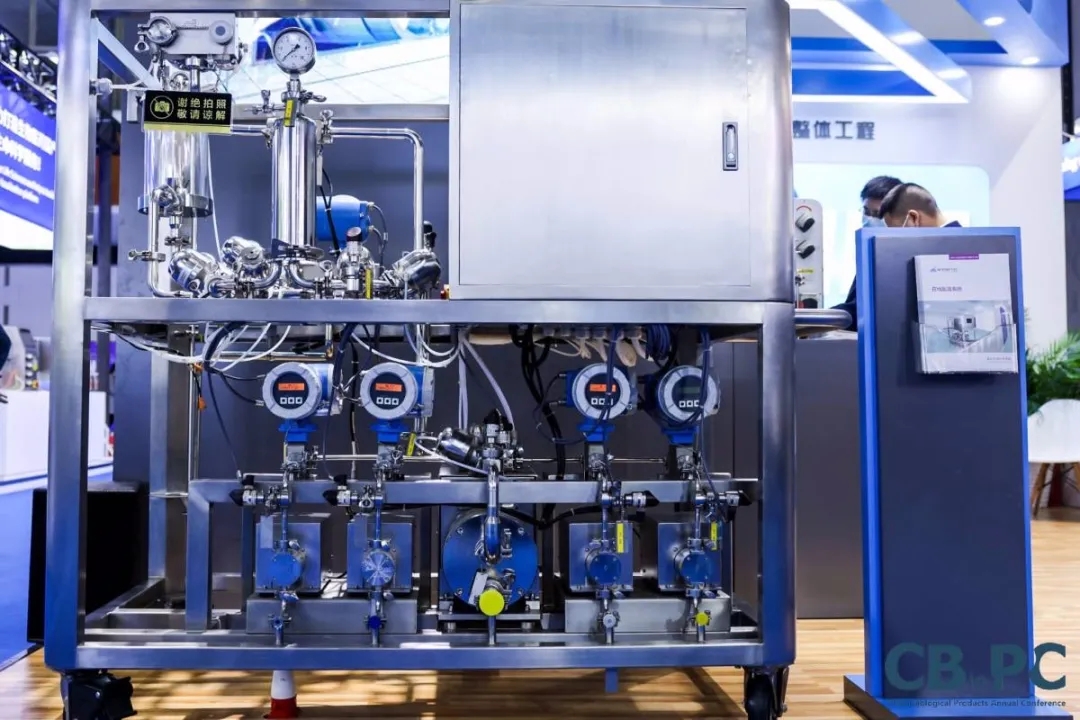

Inline buffer dilution system

It is now widely used in the downstream production of biopharmaceutical fields such as monoclonal antibodies, vaccines, antibiotics, insulin, recombinant proteins, blood products, etc. It can help customers optimize their existing buffer preparation schemes, reduce space of the preparation room and the storage room, and lower the cost of routine maintenance, cleaning and verification of the preparation and storage tanks, and meanwhile expand the scale of preparation and production. In addition, the combination of the inline buffer dilution system and buffer solution batch preparation system can meet different needs of customers and provide flexible and diverse solutions for varied production scenarios.

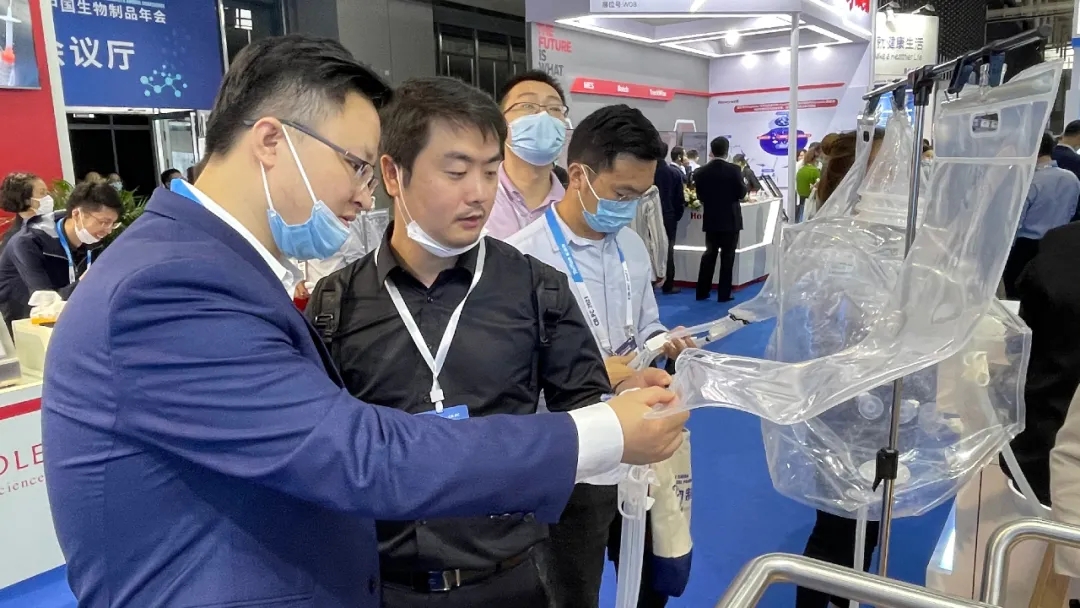

Disposable liquid mixing system

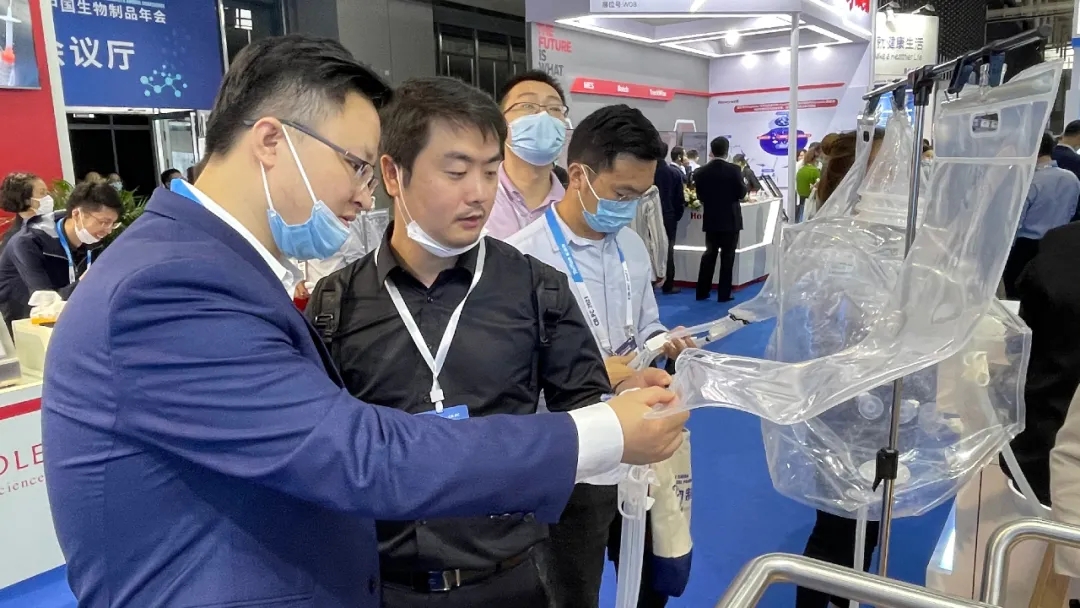

For cases of small-batch production, disposable products can help customers shorten the time for product launch, reduce verification workload, and save operating costs. Morimatsu provide solutions of disposable magnetic mixing systems and disposable storage mixing systems. With the parallel layout of stainless steel system + disposable products, Morimatsu can provide customers with the best option of products in terms of comprehensive considerations of economical efficiency, ease of operation, and supply chain stability.

As the exhibition went on, a steady stream of visitors came and halted at the Morimatsu booth to have a close contact with our products. They actively communicated and exchanged on the latest industry concepts. The on-site staff also introduced Morimatsu's latest developments in overall engineering solutions, localization of core equipment, intelligence, and digitization to the visitors.

Aiming to become the world's leading provider of core equipment, process systems and engineering solutions, Morimatsu continues to innovate in technology to help customers provide safer and more reliable products, and is committed to making people's life healthier, more beautiful and more convenient. We work together through thick and thin to depict a new blueprint of biomedicine.