Morimatsu's Customized Magic Ball Breaks Through the Bottlenecks in Cleaning Production Equipment Such As "High Viscosity, Strong Adhesion and Huge Water Consumption”

Common cleaning processes of production equipment include Clean-In-Place (CIP) online cleaning, immersion cleaning, Cleaning Out of Place (COP) offline cleaning and manual cleaning. In the actual production process, a variety of cleaning processes are usually used. In other words, first, CIP online cleaning or immersion cleaning is used for preliminary cleaning, and then the detachable parts that are not easy to clean are removed for off-line cleaning. According to the production process, samples are taken for testing, and the time period of bacteria contamination inside the equipment is obtained, and manual cleaning is carried out regularly.

With the gradual transformation of manufacturing industry to automation and digitalization, the CIP online cleaning is easy to use, and the requirements for CIP online cleaning efficiency have become stricter. The factors that affect the online cleaning efficiency of CIP are temperature, time and cleaning agent. Through improving the cleanability of equipment by optimizing the structural design is the basis to improve the online cleaning efficiency of CIP. By using reasonable equipment structure design, both the cleanability of the equipment and the overall effect of CIP online cleaning can be improved. Supported by the well-designed spray device, the direct spray cleaning of the contact surface of materials can be maximized, thereby quickly diluting and dissolving the residual materials and delivering the ideal cleaning effect.

With rich experience in cleaning production equipment, Morimatsu optimizes container design and provides customized spray ball design; besides, by improving the first pass rate of spray test with simulation program, we can provide an efficient CIP online cleaning process for production equipment. Below we will share Morimatsu's valuable experience in the cleaning process of production equipment.

1. Optimization of Pipe Interface Design

· The pipe interface of containers should be sanitary joints conforming to ASME BPE, and the interface such as Clamp, Union and NA, which are easy to clean, disinfect or disassemble, should be preferred; and the pipe flange interfaces with longer extension should be reduced to avoid the use of pipe interfaces with cleaning dead angles.

· The extension length of the pipe interface should be minimized, and the normal setting should be preferred unless necessary to reduce the cleaning dead zone;

· The pipe interfaces are arranged around the spraying device, all the pipe interfaces are within the flushing radius of the spraying device, and the spraying device is the best in the imaginary extended cylinder of the pipe interfaces;

· The metal contact surface of the product should meet the requirements of ASME BPE Table SF2-2.2-1, and the product contact surface should be cleaned and passivated before being put into use.

2. Customized spray device

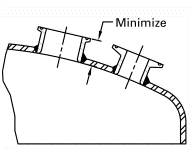

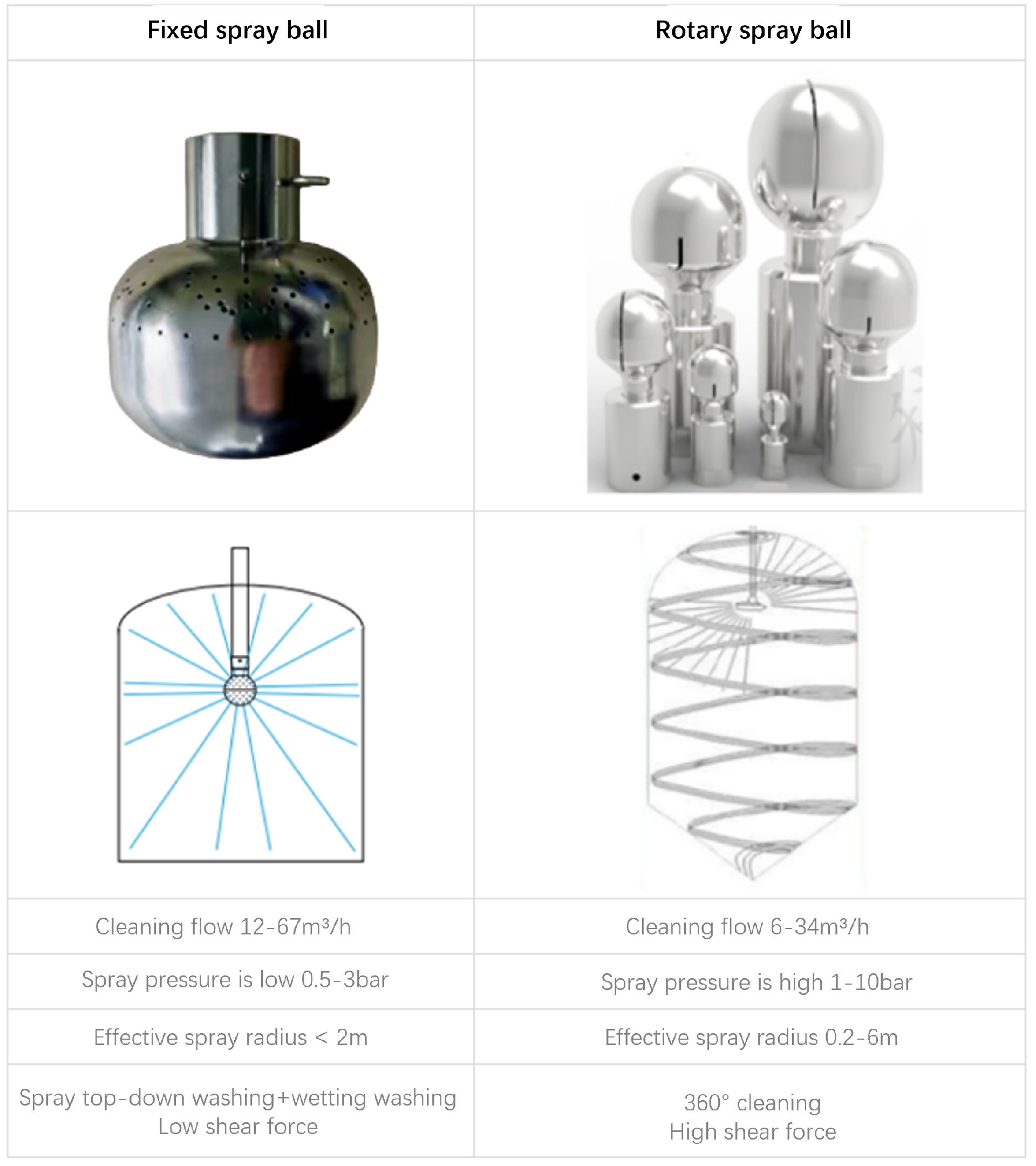

For products with strong adhesion to the tank wall, it is necessary to wash directly to remove the residues. So the rotary spray ball with greater impact force is generally preferred. Compared with the fixed spray ball, the cleaning time of the rotary spray ball is shorter and the CIP cleaning energy consumption is lower.

· For large-size equipment, multiple spray devices should be set, and the effective impact radius of each spray device should overlap each other, thus completely covering the whole equipment;

· For large-size interfaces such as manholes and mirrors, spray balls can be set separately and used in combination with the main spray balls to deliver accurate coverage of cleaning dead zones;

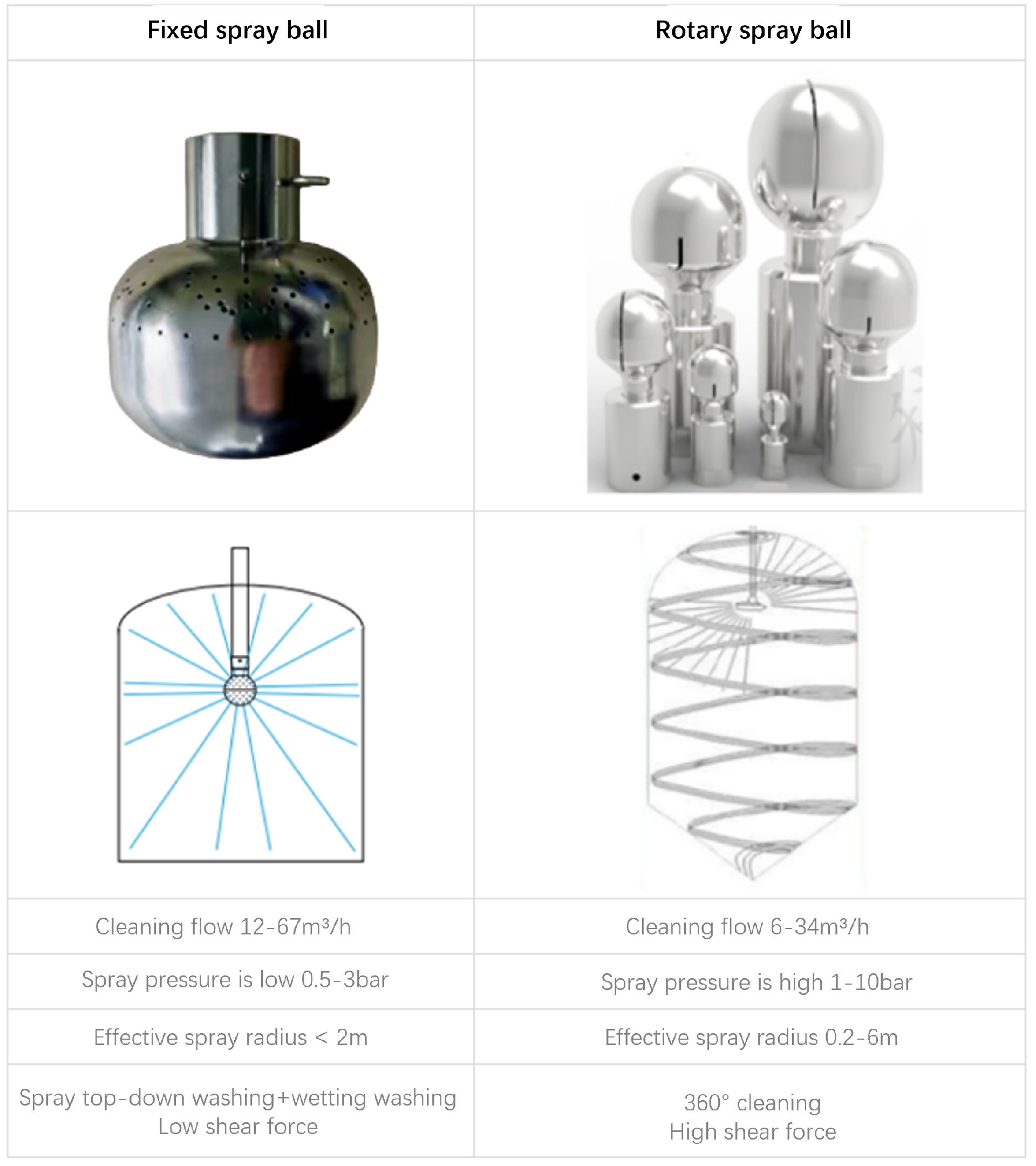

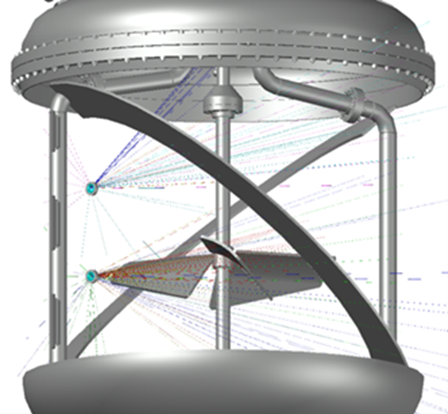

· For the equipment with upper mechanical stirring, at least two spraying devices should be set up due to the shielding of the stirring shaft to deliver 360° coverage;

· For equipment with mechanical stirring, a spraying device should be installed on the side wall of the tank to clean the negative side of the stirring blade. As the stirring is in a rotating state at this time, it is easy for directional cleaning to offer a good cleaning effect, and the rotating ball will consume a lot of cleaning capacity instead.

In summary, with complicated internal structures such as stirring, it is not enough to meet all cleaning challenges simply by relying on the rotary spray ball. Therefore, it is a faster and more efficient comprehensive solution to cover a large area with rotary spray balls and clean specific positions with fixed spray devices. In order to ensure the cleaning of specific positions, it is necessary to design and simulate the fixed spraying device. Morimatsu has been continuously iterating and innovating in directional design and simulation, striving to provide customers with efficient equipment to meet the cleaning needs.

3. Optimizing simulation program

· Implementing software upgrade strategy to improve the quality of spray simulation, so as to promote the sustainable development goals;

· Optimizing the spray simulation program to reduce the time required for simulation of side wall spray device;

· Accurate cleaning the internal parts of the equipment and reducing the rework times of the spray device;

· Improving the first pass rate of spray experiment and saving manpower and material costs.

Application Case

Cleaning of Production Equipment in Personal Care Industry

01 Cleaning problems of personal care production equipment

Personal care industry has a wide range of products, including cosmetics, personal cleaning products and perfumes. In addition, innovative products and formula upgrades are emerging one after another every year. The majority of these products have high viscosity, strong adhesion and hydrophobicity, and their residues are difficult to be completely removed. Moreover, the production process is often faced with the switching of different batches and product lines, which leads to complicated and lengthy cleaning procedures and large energy consumption.

02 Customized spray ball solution

Based on the characteristics of personal care products, Morimatsu can customize the fixed spray ball for customers. Through accurate opening and high-precision processing technology, it can cover every corner of the process contact surface under low spray pressure. In the delivered projects of world-famous daily chemical brands, it has achieved 100% online cleaning coverage of its personal care products production equipment. While the cleaning time is shortened, the CIP energy consumption and production cost are significantly reduced, which provides a strong guarantee for production efficiency improving and economic benefits and has been highly recognized by customers.

The customized spray ball of Morimatsu not only brings advantages to the cleaning of production equipment, but also makes important contributions to promoting sustainable development. Customer demand-oriented and technological innovation-driven, Morimatsu will adhere to the concept of green environmental protection and further provide personalized solutions.

The article is provided by the Technology Division of Morimatsu LifeSciences

About Morimatsu LifeSciences

Morimatsu LifeSciences, one of the key business segments of Morimatsu International Holding Co., Ltd. (Morimatsu International, stock code: 2155.HK), mainly consists of Shanghai Morimatsu Pharmaceutical Equipment Engineering Co., Ltd., Morimatsu (Suzhou) Life Technology Co., Ltd., Shanghai Morimatsu Biotechnology Co., Ltd., Pharmadule Morimatsu AB (Sweden) and its subsidiaries, which serves the pharmaceuticals, bio-pharmaceutical, cosmetic medicine, FMCG (cosmetics, baby, women & home Care, health care, fabric & home care, food, beverage, nutraceuticals) and other industries, providing customers with "core equipment+value-added services+digital intelligent overall factory solutions and services" ("MVP Solutions&Services"), focusing on core equipment, stainless steel process systems, disposable process systems, consumables, laboratory solutions, digital and modular factory solutions and services.

As a diversified multinational company, Morimatsu has opened subsidiaries or advanced manufacture plants in China, Japan, Sweden, United States, India, Italy, Singapore, and has delivered different forms of products and services to more than 40 countries and regions so far, by its global footprint of an efficient and professional team.

Forward-Looking Statements

The information in this press release may include some forward-looking statements. Such statements are essentially susceptible to considerable risks and uncertainties. The use of "predicted", "believed", "forecast", "planned" and/or other similar words/phrases in all statements related to our company is to indicate that the statements are forward-looking ones. Our Company undertakes no obligation to constantly revise such predicted statements.

Forward-looking statements are based on our Company management's current perspectives, assumptions, expectations, estimations, predictions and understanding of future affairs at the time of the making of such statements. Such statements are not guarantees of future development and are susceptible to the impact of risks, uncertainties and other factors; some are beyond the control of our Company and unpredictable. Subject to the influence of future changes and development in our business, competition environment, political, economic, legal and social conditions, the actual outcomes may differ significantly from the information contained in the forward-looking statements.